OUR PRODUCTS

OUR PRODUCTS

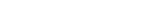

Multi-purpose Sewing Machine

| Specification | Description |

|---|---|

| Machine Speed | 40 – 80pcs/min |

| Tube Type | Paper, Sandwich, Laminating Tube |

| Tube Length | 650-1200mm |

| Tube Width | 260-550mm |

| Gusset Width | 0-150mm |

| Corrugated Paper Width | 55mm |

| Latex and Thermal Tape Width | 60mm |

| Sewing head and speed | DN - 2, 25M/min |

| 1stCutter | Air Cylinder Time |

| 2nd Cutter | Servo Motor Time |

| Tube feeding method | Simens Motion program |

| Operating method | 19-inchTouch Screen |

| Air Capacity | 5-6 Kg/cm2 |

| Electrical Specification | 220/380*60Hz * 3P * 15W |

| Machine Weight | ~ 2,500 Kg |

| Machine Dimensions | Length 9,657 * Width 2,508 * Height 2,197 |

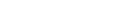

Automatic Feeder

| Specification | Description |

|---|---|

| Speed | 120pcs/min (max.) |

| Tube Material | Paper, Sandwich, Laminating Tube |

| Tube Length | 650 - 1200mm |

| Tube Width | 260 - 550mm |

Features

- Application of CADCAM program to forward and reverse units to change tube position during operation

- Front and rear cylinders can be adjusted to effectively eliminate double-sheet feeding when the tube is elevated.

- Air blasts from the guide pipe and guide side during tube feeding facilitate tube alignment.

- Air units can be enabled/disabled on the touchscreen.

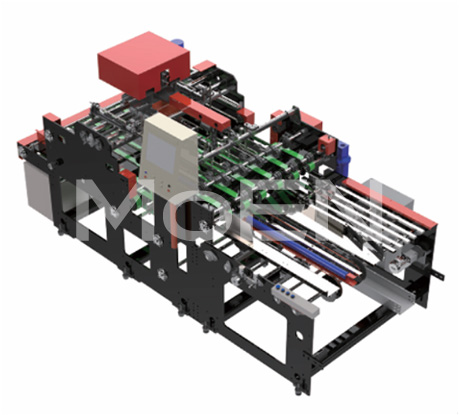

Multi-purpose Sewing Part and Discharge/Transfer Part

| Specification | Description |

|---|---|

| Speed | 70pcs/min (max.) |

| Tube Material | Paper, Sandwich, Laminating Tube |

| Tube Length | 650 - 1200mm |

| Tube Width | 260 - 550mm |

Features

- The stiffener cut position can be selected either before or after the tube using a servo motor.

- Front and back tape lengths adjustable during production (with sensor fine-tuning)

- A cushion guide device is installed to prevent defects in sandwich tube production that do not reach the inside of the corrugated paper.

- Air cylinders are installed on the take-out roll to ensure reliable discharge of finished bags.

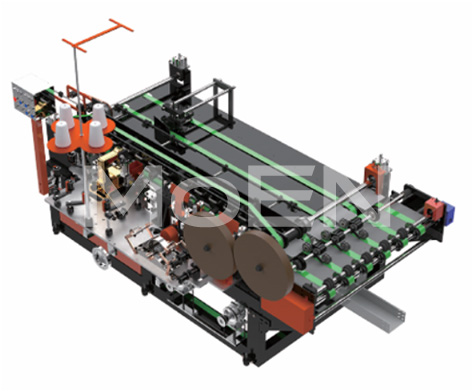

Counter Stacker

| Specification | Description |

|---|---|

| Speed | 120pcs/min (max.) |

| Tube Material/td> | Paper, Sandwich, Laminating Tube |

| Tube Length | 650 - 1200mm |

| Tube Width | 260 - 550mm |

Features

- An air cylinder is installed at the front to prevent sagging in laminated bag production, supporting the front of the bag in case of drops and stabilizing bag stacking.

- Adjustability based on bag width

- Air Cylinder Enable/Disable Switch installed

- Air cylinders installed along the length of the bag

- First-stage air cylinder to secure the final bag when loading a bundle of 25 bags, Second-stage air cylinder fork installed to ensure clearance during ejection

- Increased productivity and reduced labor through automation of finished goods when using two or more multi-purpose sewing machines

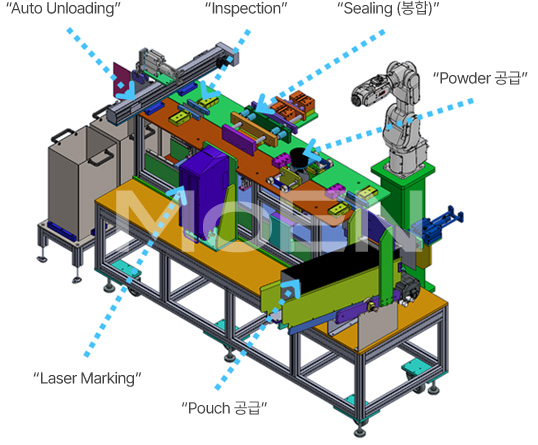

Power Packing Multi Carrier

| Item | Spec |

|---|---|

| Pouch Magazine | About 2,500 pcs per cycle are manually loaded by the operator. |

| Pouch Feed | Suction Pad –Ejector (Vacuum Generator), Air Cylinder |

| Pouch Transfer | A.C Servo Motor: X axis Pitch transfer |

| Powder Feed | Conventional articulated robot (6 axis), 200g supply |

| Suction of scattered powder | Connected to the main duct |

| Upper Pouch Sealing | Heat sealing with an electric heater |

| Laser Marking | Laser marking and barcodes are directly printed on the pouch face simultaneously during the sealing process. |

| Inspection | Verification of Laser Marking Bar Code Recognition Check for powder presence |

| Automatic Unloading | X-Robot, Servo motor, Y-Cylinder, Gripper |

| Separate loading into 3 baskets with NG, 3EA, and 1EA |

Where could I use the Multi-Carrier-System? Typical applications

Carrier grouping for certain steps

in the production line

in the production line

Synchronize with external axis

Variable stopping, exactly where

it's required

it's required

MCS taking over as X-Axis

Multi-Carrier-System

Cooperation partners Siemens and Moen bring in their core competences

Moen

Long-standing experience in automating movements

in key processes of the machine

- Magnetic package/carrier

- Linear motor

- Measurement system/encoder

- Standard belt, basic frame

Siemens

Long-standing experience in machine automation and

synchronized motion control

- SIMATIC S7-1500T/SINAMICS S120

- TEC RAILCTRL/library “LRailCtrl”

- Tool-set for design, simulation and engineering:

BOM Builder, Web Server and Modular Application Creato